Laser Drilling

EBTEC Corporation is a leading supplier in the US laser drilling industry serving; Aerospace, Medical, Power Generation, and Industrial markets.

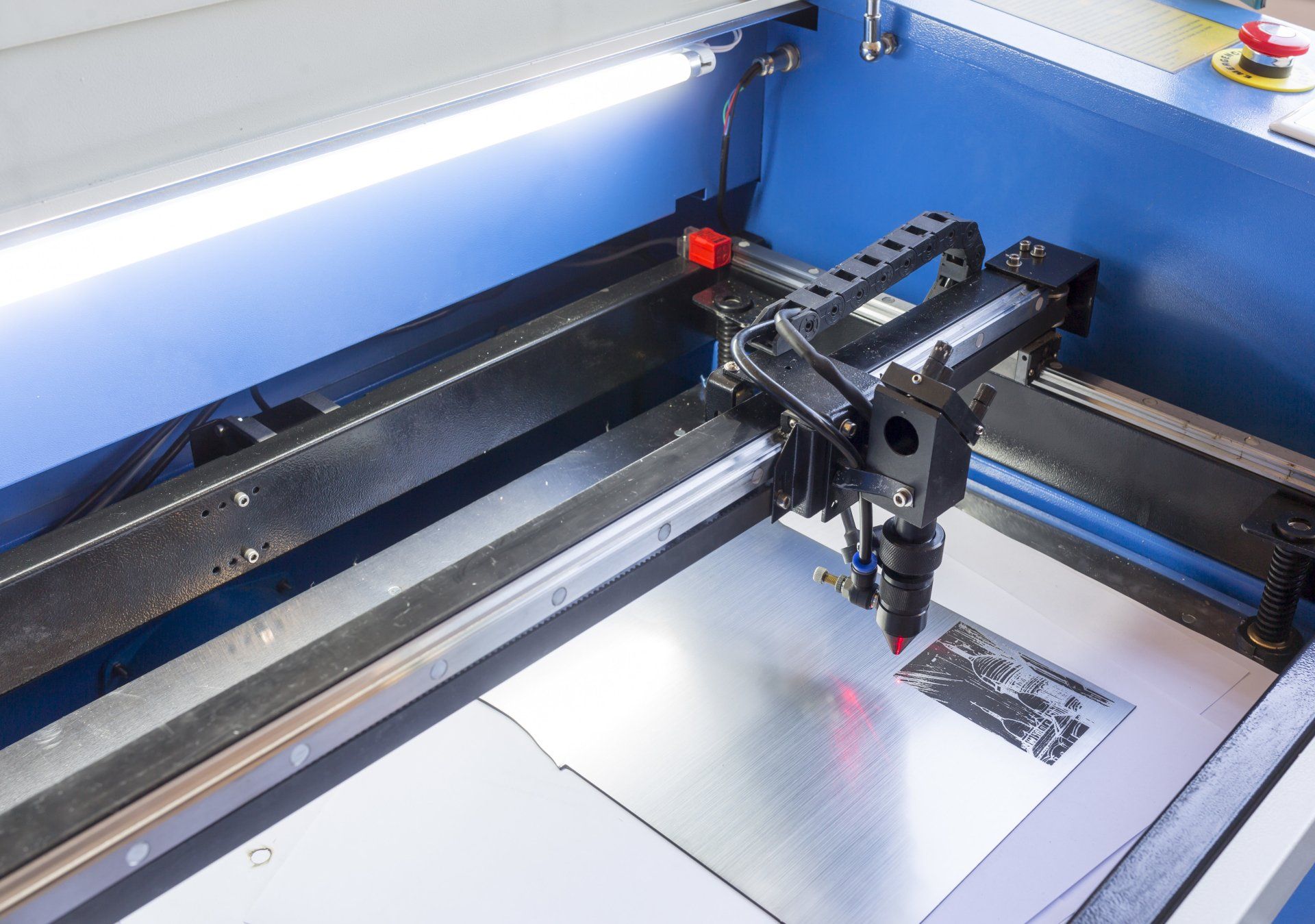

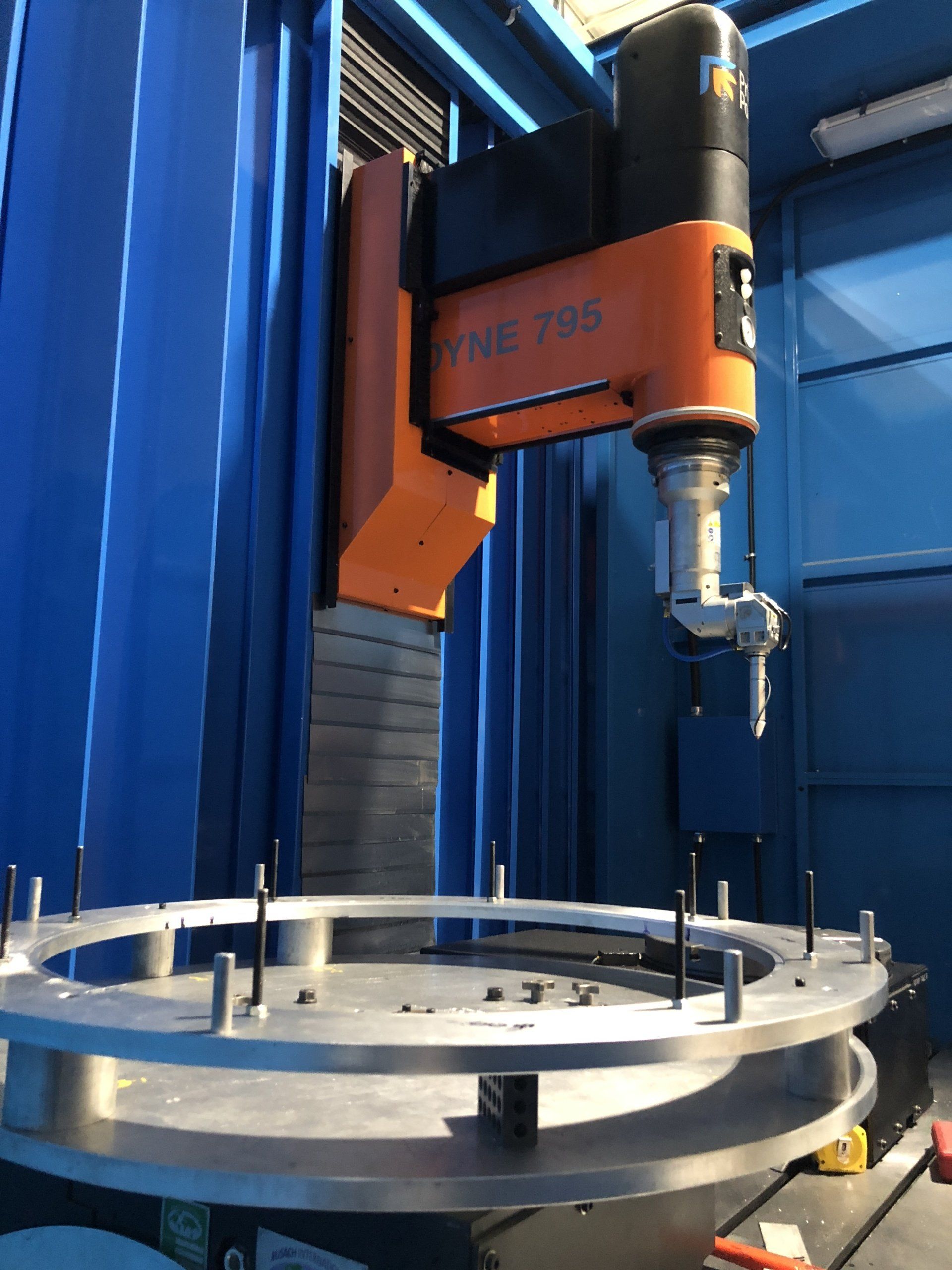

EBTEC operates 15 multi-axis laser machines , capable of handling your precision Laser Drilling needs.

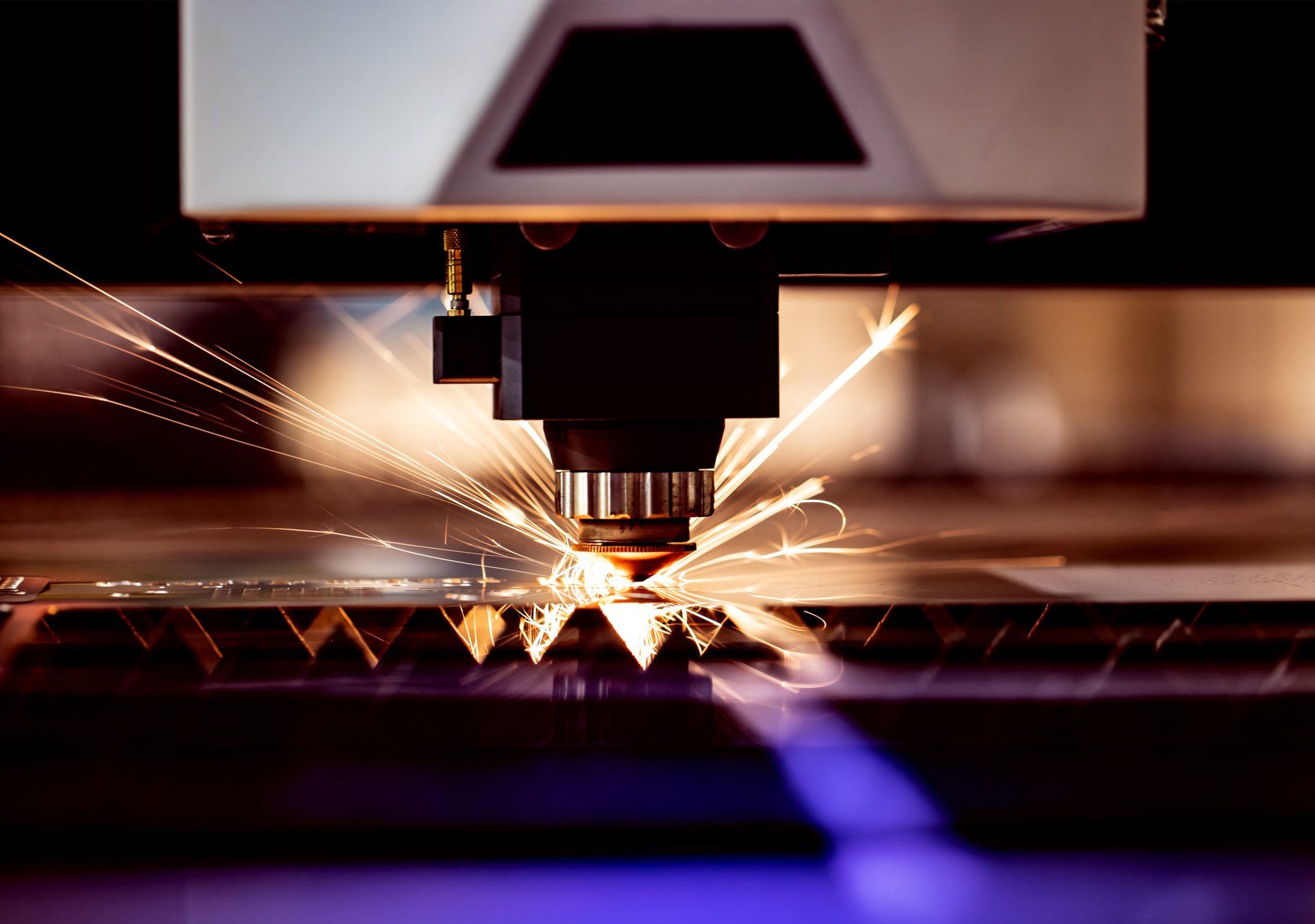

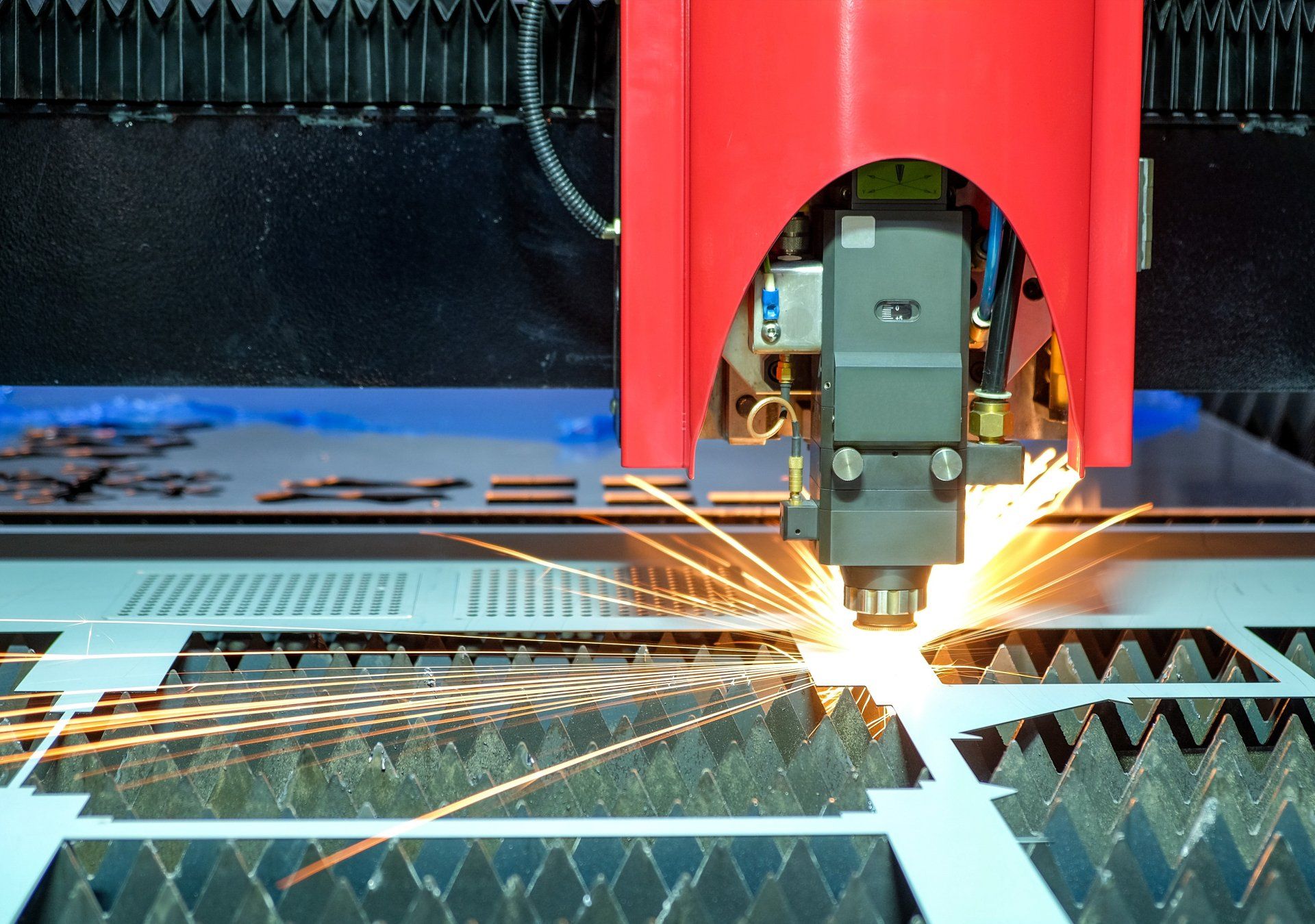

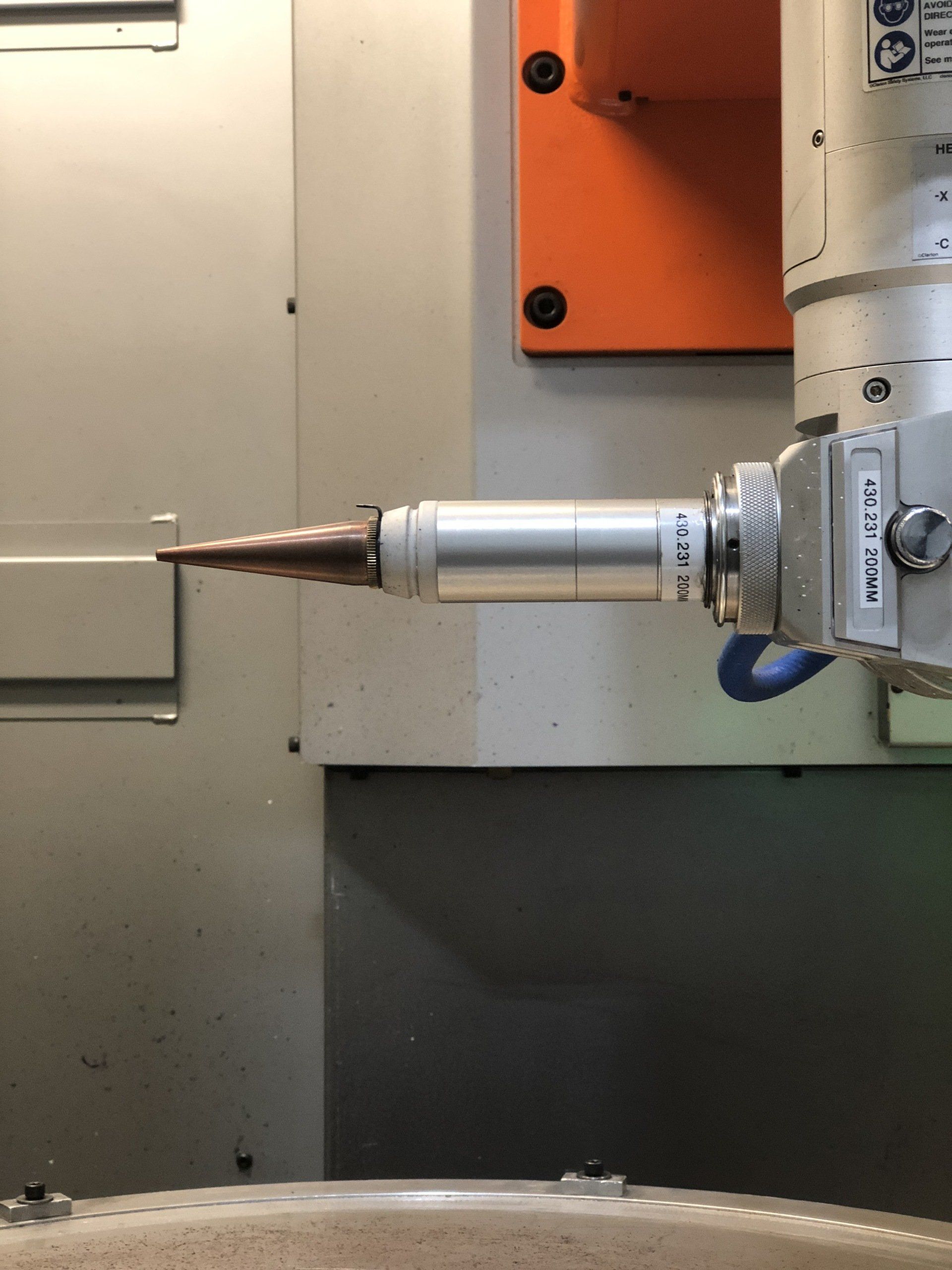

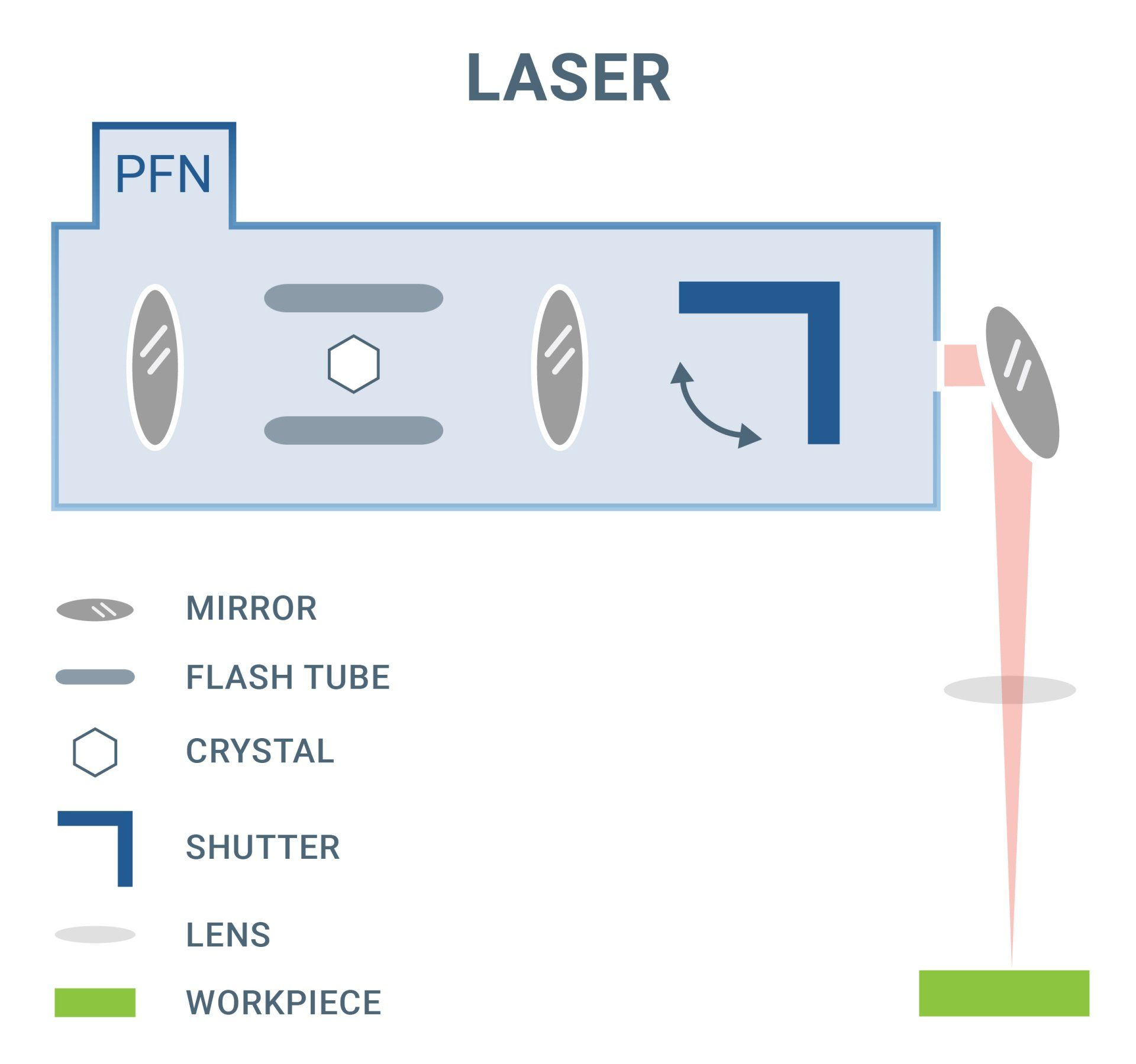

The collimation of light (photons) used to impart energy on a vast array of materials to drill challenging holes. The laser system, coupled to a 5-axis CNC motion control system, becomes a robust drilling machine tool. EBTEC’s Laser drilling systems are used to produce complex through-hole drilling in customer components across multiple industries. “LASER – light amplification by stimulated emission of radiation”

We excel in prototype through large-scale production applications and have highly skilled engineering and technical staff available to discuss your potential opportunities.

Our machines utilize advanced Nd-Yag laser systems, and “kW class” fiber laser systems for our laser drilling technologies. Laser output powers range from 30watt to 20kw. Additionally, we can perform laser cutting, laser welding, and laser engraving on your finished components.

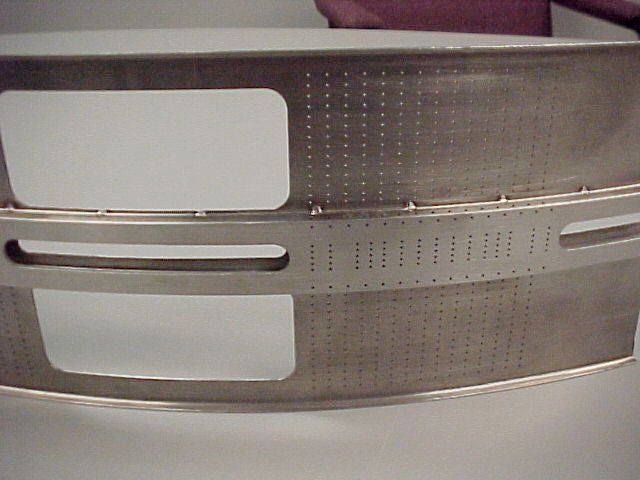

Conventional drilling techniques for holes at .015” diameter……near impossible. Laser drilling of these holes, are routinely processed. Whether it is one hole or thousands of holes, the laser process is suited to perform this task

EBTEC maintains AS9100 / ISO9002 certification and NADCAP non-conventional machining certifications as well as a host of OEM certifications.

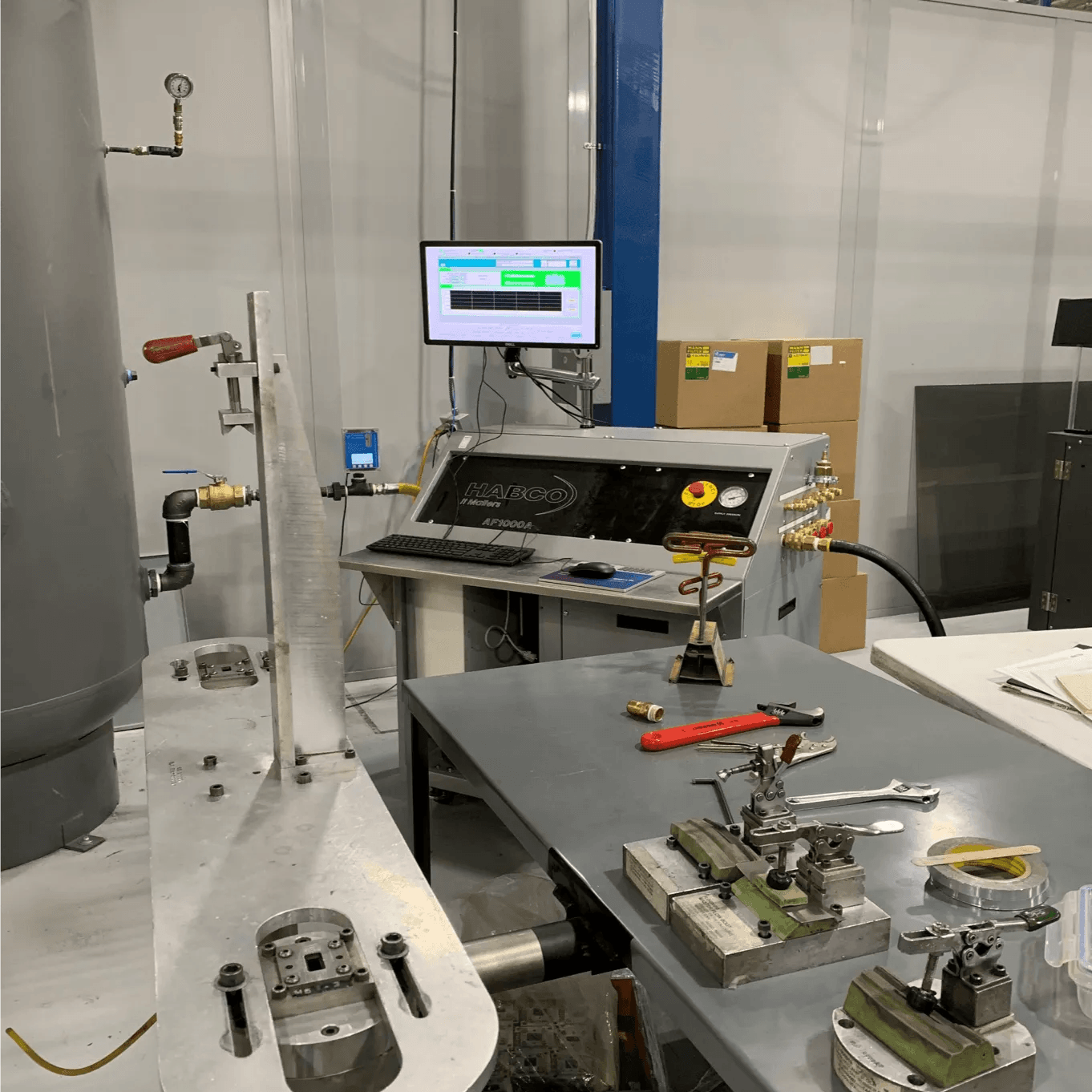

Airflow Bench

Large benefits can be made with laser drilling when tens, hundred, and thousands of holes are required. Measuring the holes sizes and positions are often time more difficult that the drilling.

EBTEC has two certified airflow benches to help solve this issue. The size and population of the holes in a component can be measured by the amount of air passing through the holes.

This airflow process measures precisely what modern aircraft and engine component manufactures specify.

EBTEC is NADCAP certified for airflow, GE certified and PWA Certified.

About Laser Drilling

Laser Drilling is a process that can be used to drill alloys and composites that cannot be drilled by conventional methods.

The Value of Laser Drilling

Benefits of Laser Drilling Services:

- Processing of high-alloy metals without difficulty

- Low tool cost, no tool wear

- Drills angled holes and difficult access holes

- Economic setup time

- High repeatability with multi-axis CNC laser control

- Faster than any conventional method

- Ability to drill holes smaller than conventional methods allow

- Creating entrance angles not possible with contact machining

- Minimal mechanical force on workpiece

- Low dimensional variability

- Low distortion

- Cost Competitive

Limitations of Laser Drilling Services:

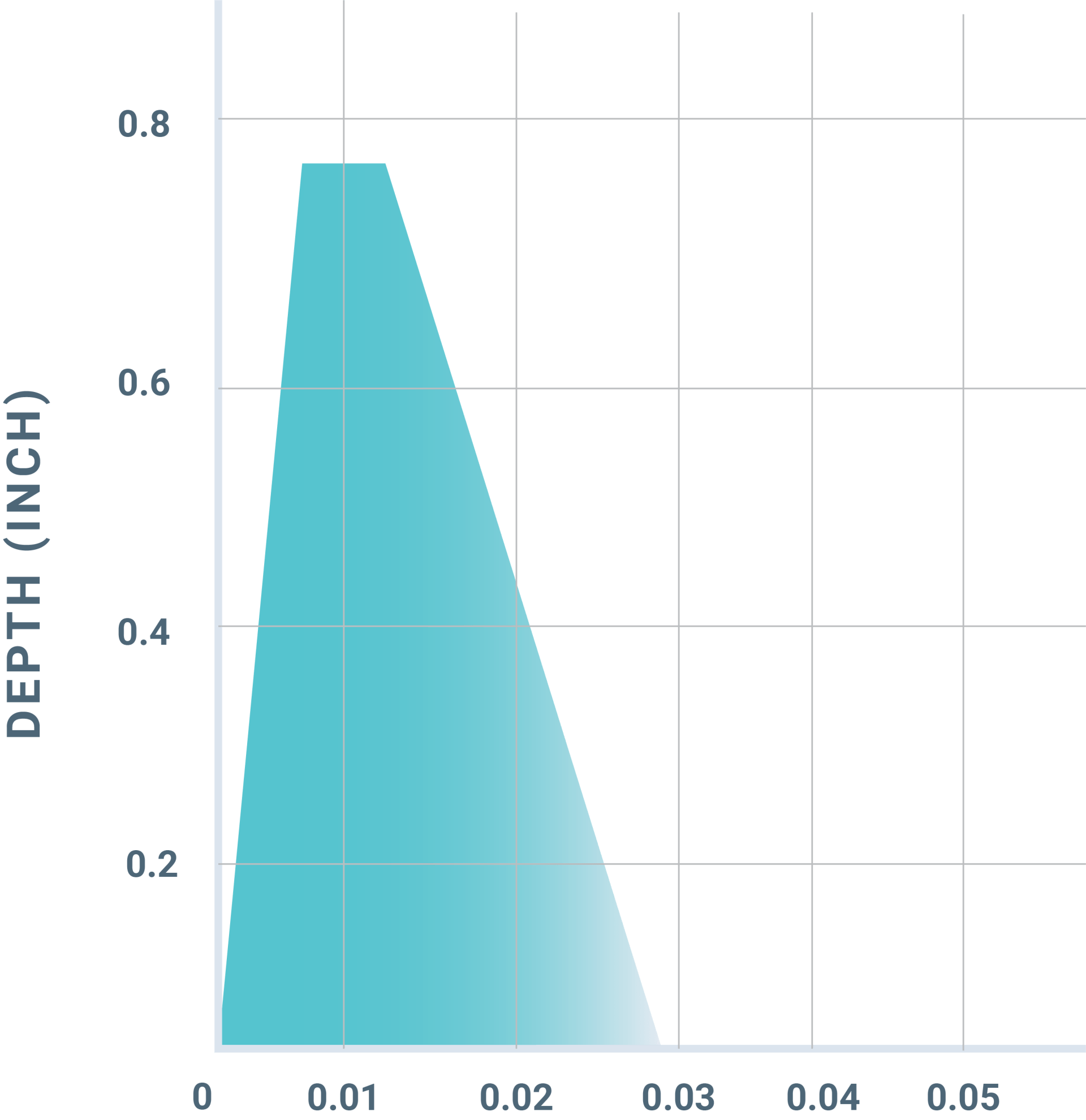

- Laser holes are tapered to some extent (approximately 1% of the drill depth)

- Cannot drill a blind hole to a precise depth

- Adherent metal needs to be removed from exit hole on some materials

- Depth to width ratio – very deep holes are difficult to drill

- Materials reflectivity eliminates “some” materials from process

The Laser Drilling Process

YAG Laser Percussion Drill Penetration

How it Works

Contact Us

Contact Us

We will get back to you as soon as possible.

Please try again later.