Laser Welding

Laser Welding

EBTEC has the capacity to address our customers’ precision Laser Welding needs, from prototype through full-scale production.

EBTEC strives to ensure fast, precise component manufacturing and servicing for our customers.

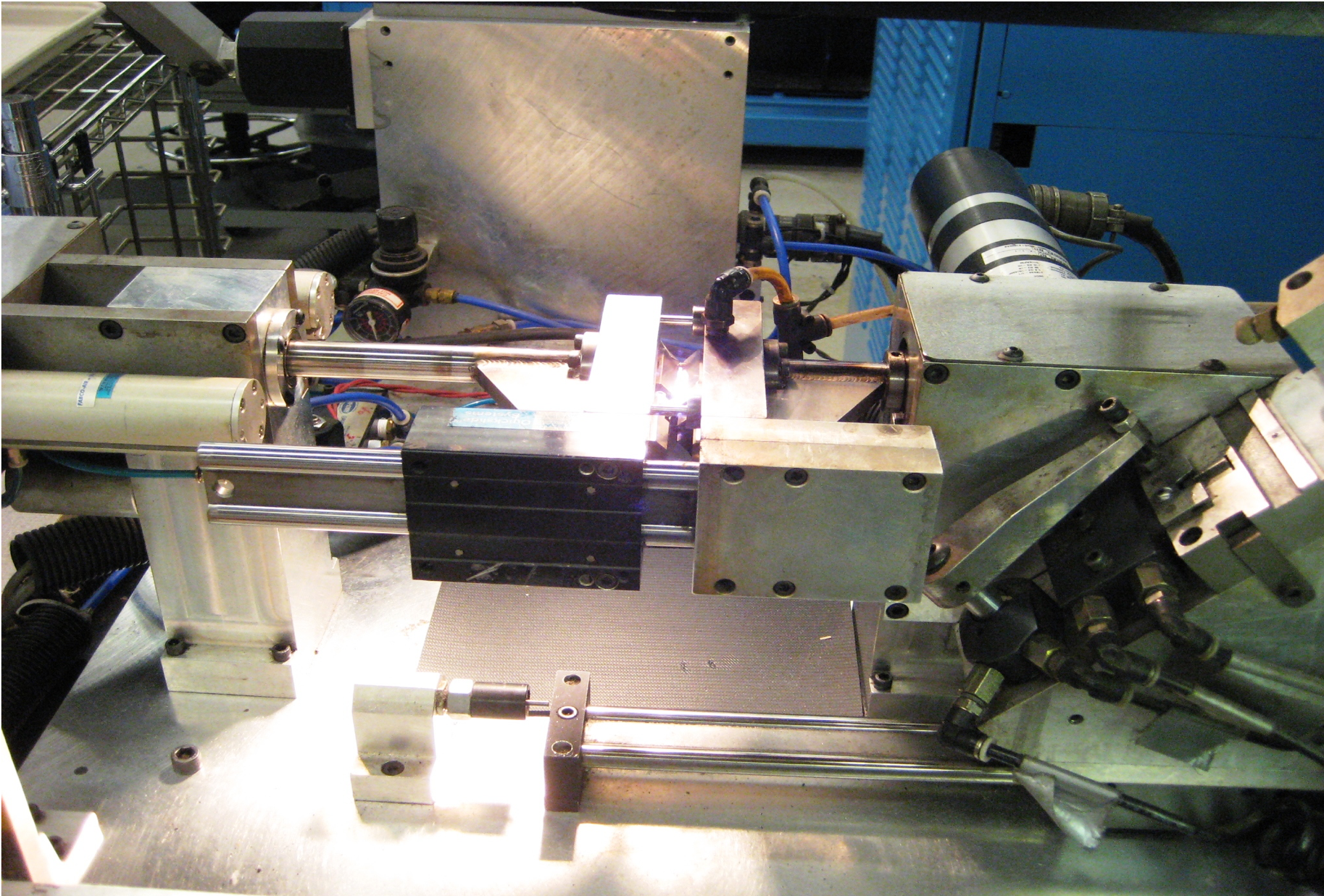

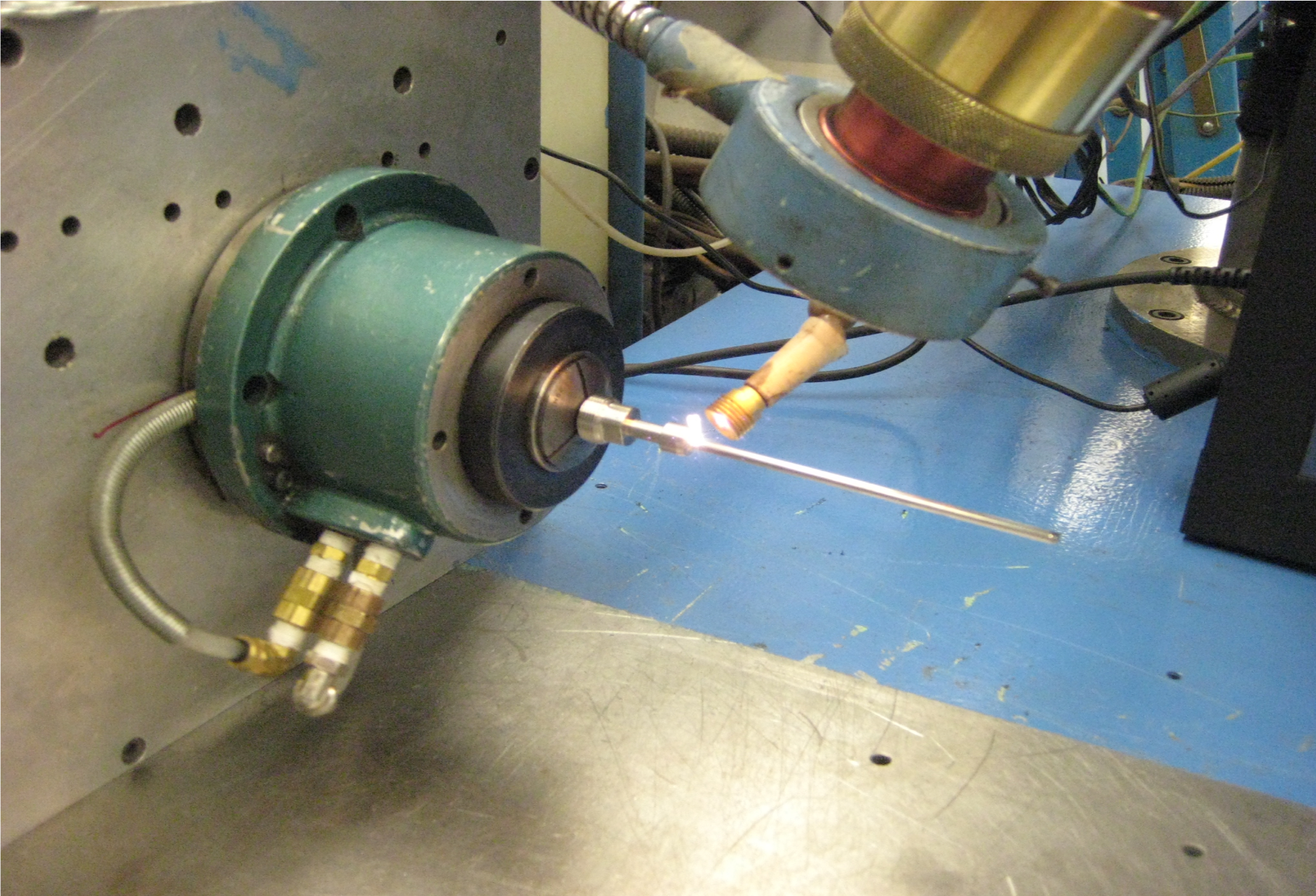

Our facilities house 15 laser machines that utilize advanced YAG and Fiber welding technology, with output ranging from 30watt to 20kw.

All of our laser machines are CNC controlled. Some of the laser welding machines utilize a 5- or 6-axis control and others utilize a fully articulated wrist.

About Laser Welding

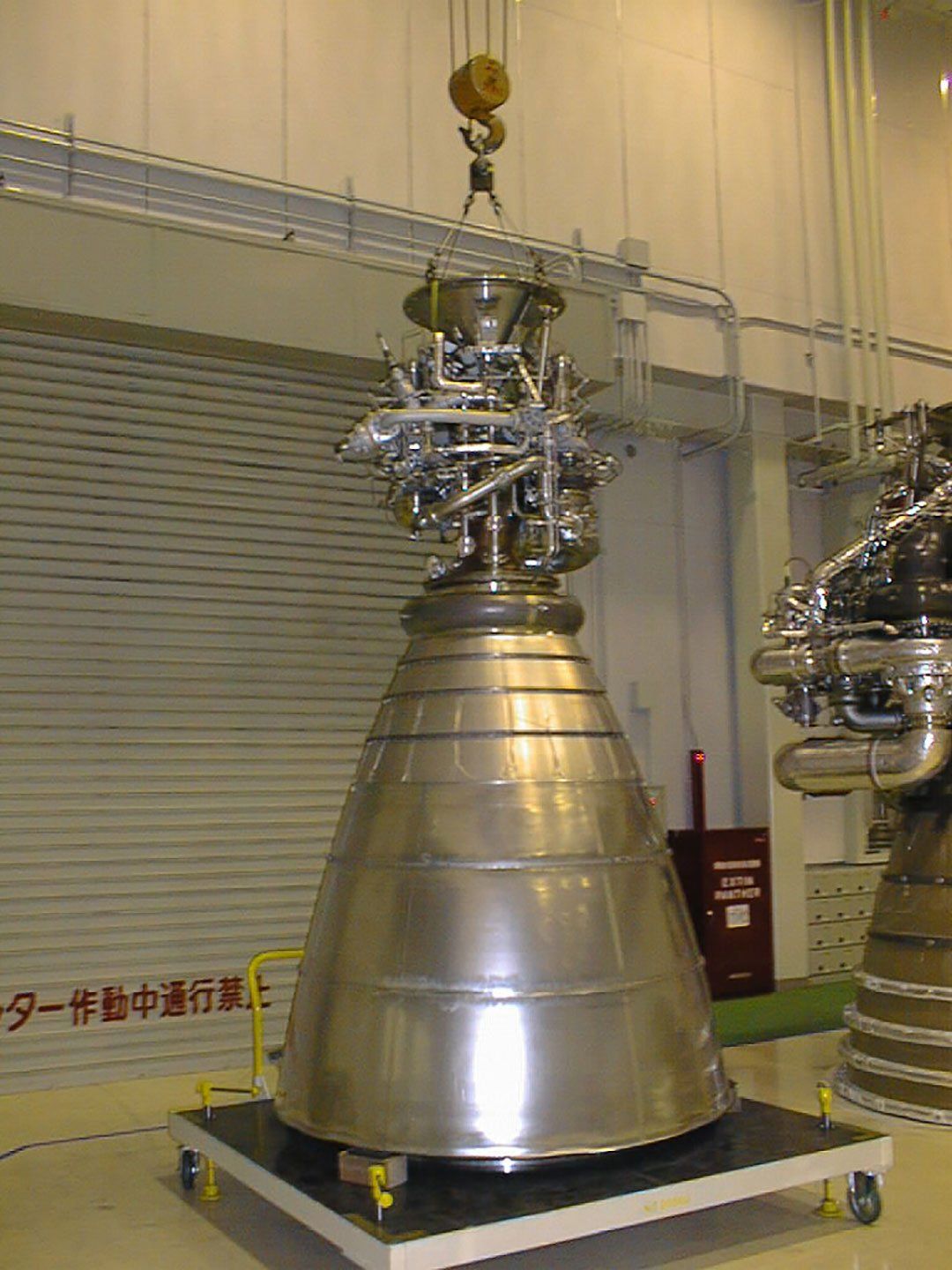

Laser Welding is a process that joins ferrous metals, stainless steel, precious metals, and alloys to themselves or each other.

Our Laser Welding Service can offer you and your components the following advantages:

- 5- or 6-axis laser control

- Extreme precision and minimal distortion

- Low heat input

- Excellent finished appearance

- No fillers or fluxes required

- Fast, cost-effective production

- Highly repeatable

The Value of Laser Welding

Benefits of Laser Welding Services

- Processes high-alloy metals without difficulty

- Can be used in open air

- Can be transmitted over long distances with a minimal loss of power

- Narrow heat-affected zone

- Low total thermal input

- Welds dissimilar metals

- No filler metals necessary

- No secondary finishing necessary

- Extremely accurate

- Welds high-alloy metals without difficulty

Limitations of Laser Welding Services

- Rapid cooling rate may cause cracking in certain metals

- High capital cost

- Optical surfaces easily damaged

- High maintenance cost

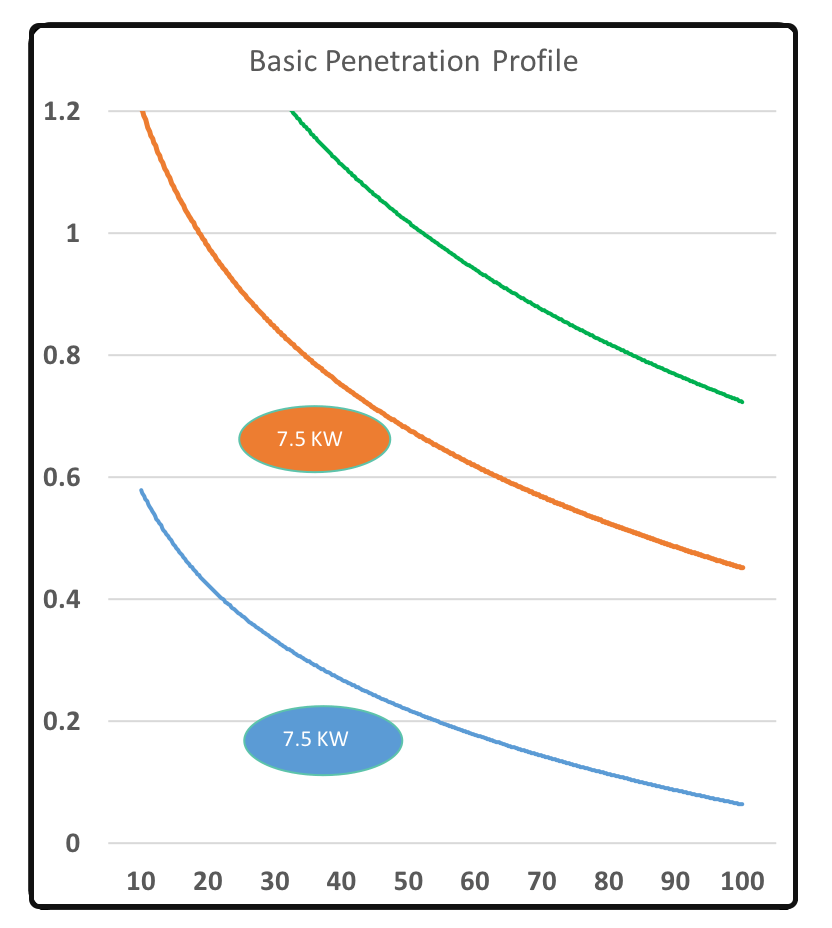

Laser Welding Speeds

Laser Welding Speeds

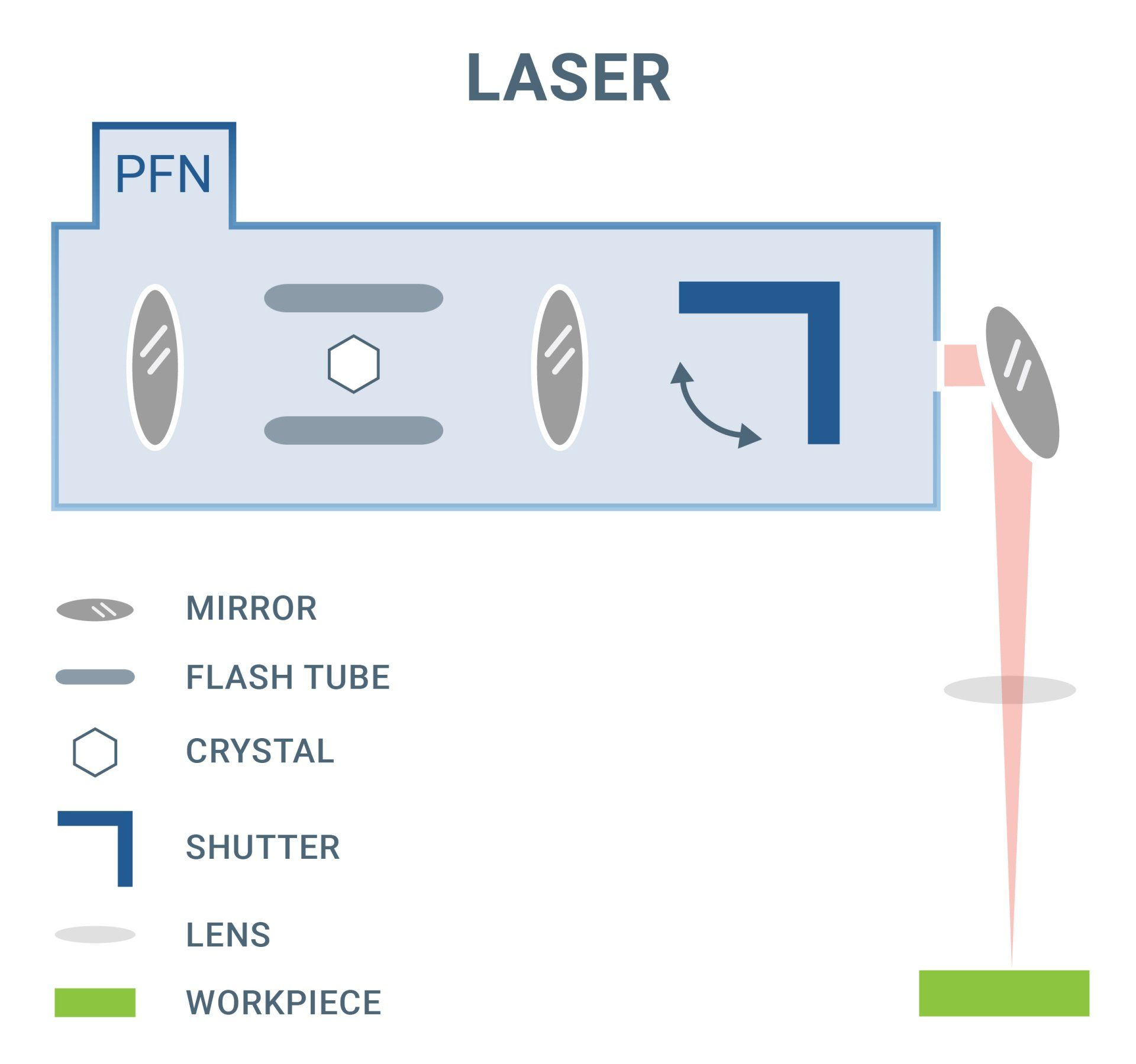

The LASER, an acronym for “Light Amplification by Stimulated Emission of Radiation,” is a device that produces a concentrated, coherent beam of light by stimulating molecular or electronic transitions to lower levels, causing the emission of photons.

In Laser Welding, the solid-state laser utilizes a single crystal rod with parallel, flat ends, with each end having reflective surfaces. A high-intensity light source, or flash tube, surrounds the crystal.

When power is supplied by the PFN (pulse-forming network), an intense pulse of light (photons) will be released through one end of the crystal rod. The light being released is of single wavelength, thus allowing for minimum divergence.

How it Works

In the Laser Welding process, 100% of the laser light will be reflected off the rear mirror, and 30 to 50% will pass through the front mirror.

The laser light will continue on through the shutter assembly to the angled mirror and down through the focusing lens to the workpiece. The laser light beam used in our Laser Welding Service is coherent and has a high energy content, and when focused on a surface, laser light creates the heat used for welding.

In our Laser Welding Services, both the workpiece and the laser beam are manipulated by means of robotics. During the Laser Welding process, the laser beam can be adjusted to varying sizes and heat intensity, from .004 to .040 inches.

The smaller size is used for welding and the larger for heat treating.

Contact Us

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Please try again later.