Waterjet Cutting

Waterjet Cutting &

Abrasive Waterjet Cutting

A supersonic stream of water, with garnet (small stones) in suspension - a tool for cutting metals.

-

About Waterjet Cutting

LEARN MORE -

The Value of Waterjet Cutting

LEARN MORE -

Waterjet Cutting Finishes

LEARN MORE -

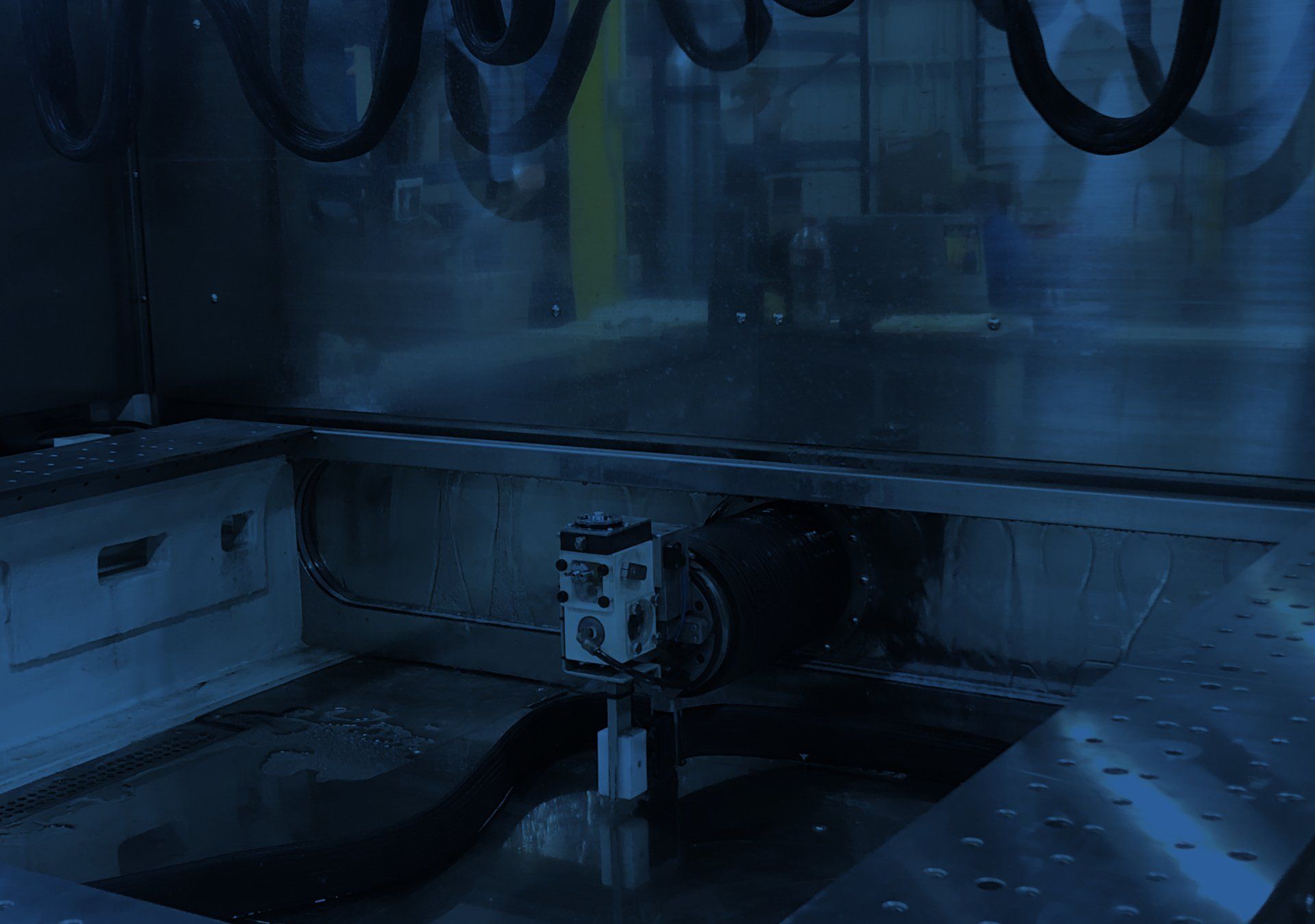

The Waterjet Cutting Process

LEARN MORE

Is Waterjet Cutting and Abrasive Waterjet Cutting The Same?

No – not really, but through some simple research we have ascertained that the common laymen’s terminology for abrasive waterjet cutting has been truncated to “waterjet” cutting. Pure water only waterjet systems are very capable of cutting operations without abrasive….but…..they are extremely limited to what they can actually process. Abrasives are added to the waterjet systems to enhance the ability to process much harder, much more dense materials such as metals, ceramics, super alloys, granite, the list goes on and on………virtually any material.

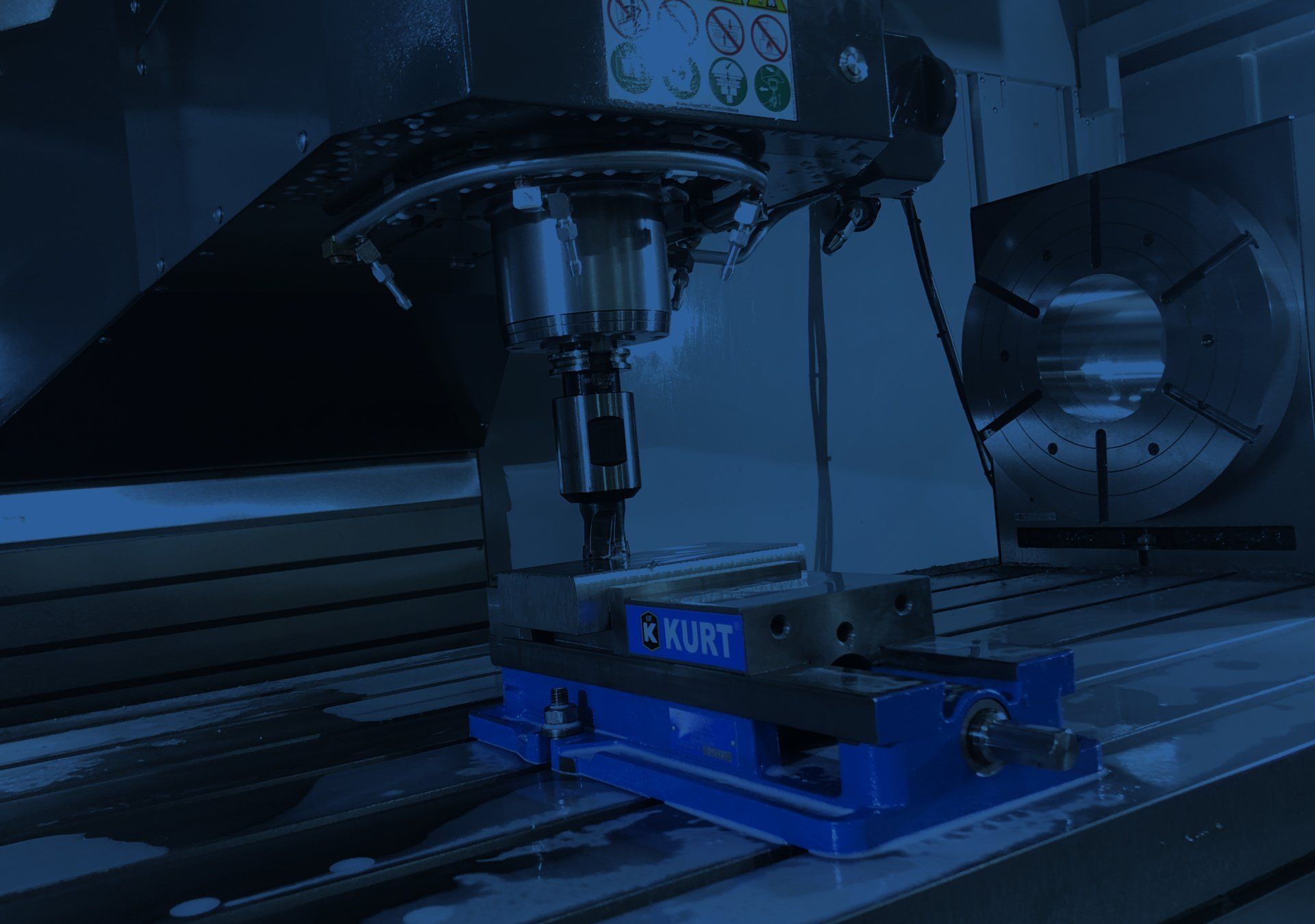

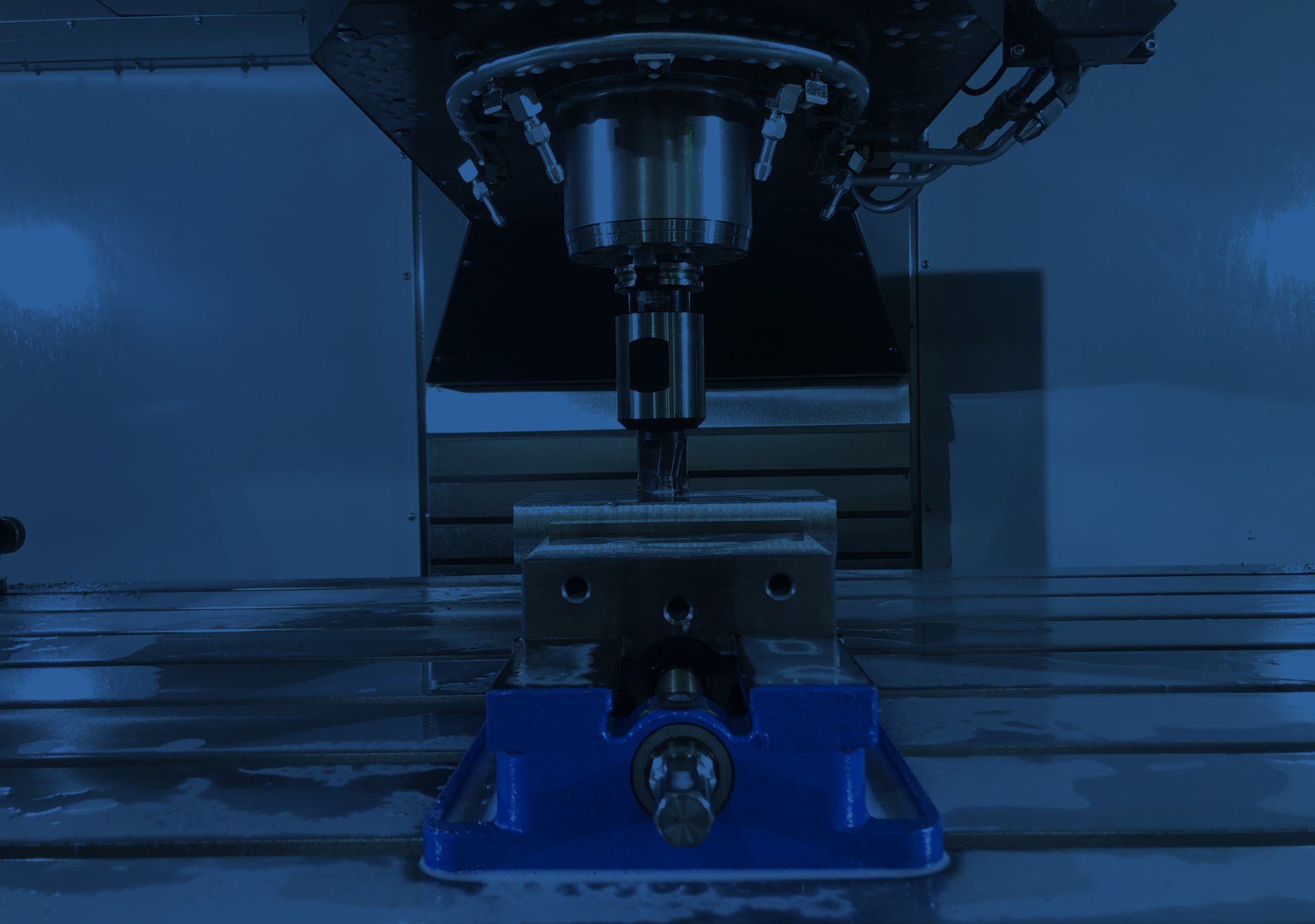

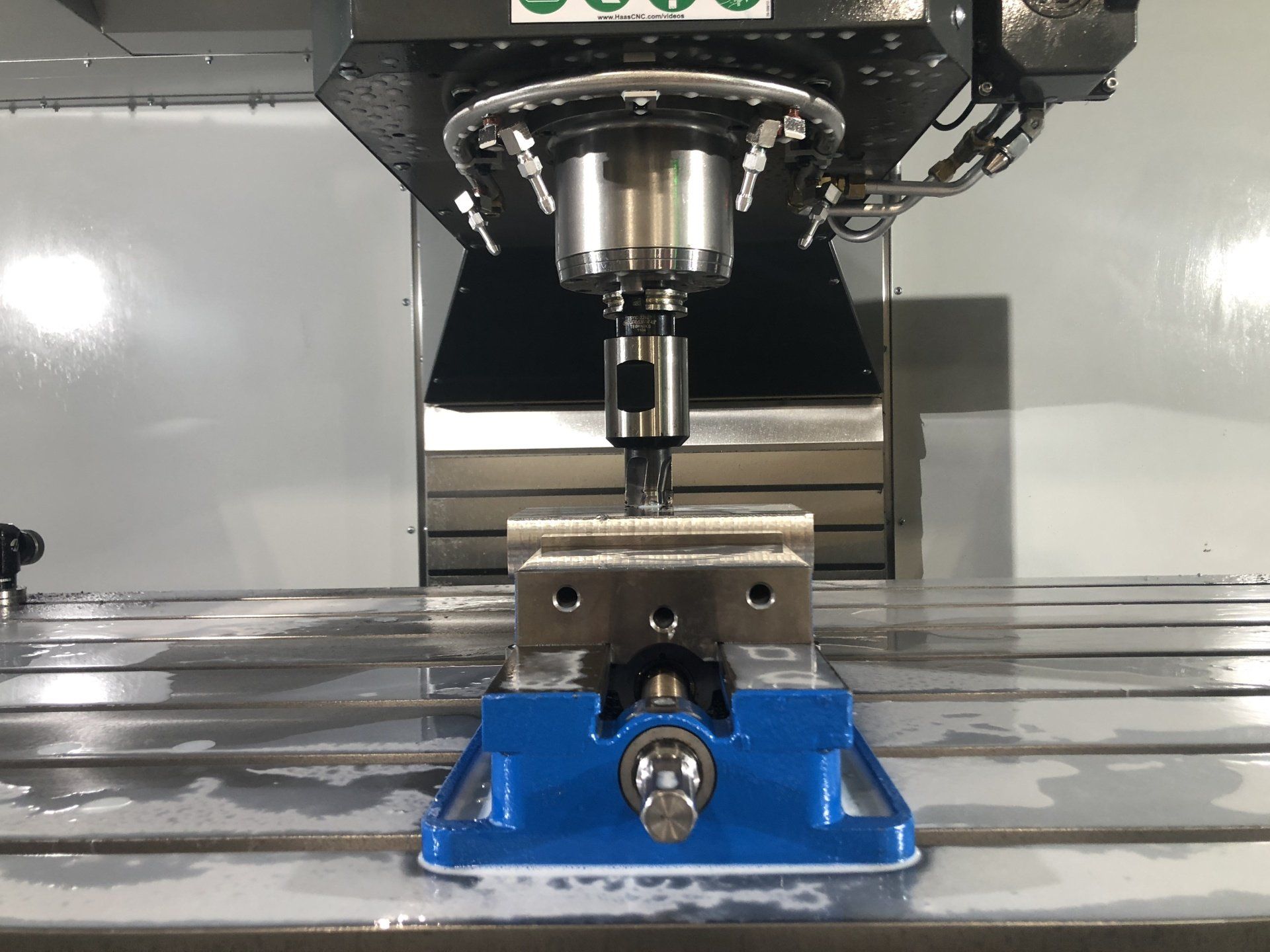

EBTEC’s Waterjet Facilities Utilize 3 Abrasive Waterjet Cutting Machines

The machines have an output of 55,000 psi. Each of these machines can operate as Waterjet cutting systems, or as Abrasive Waterjet Cutting Systems.

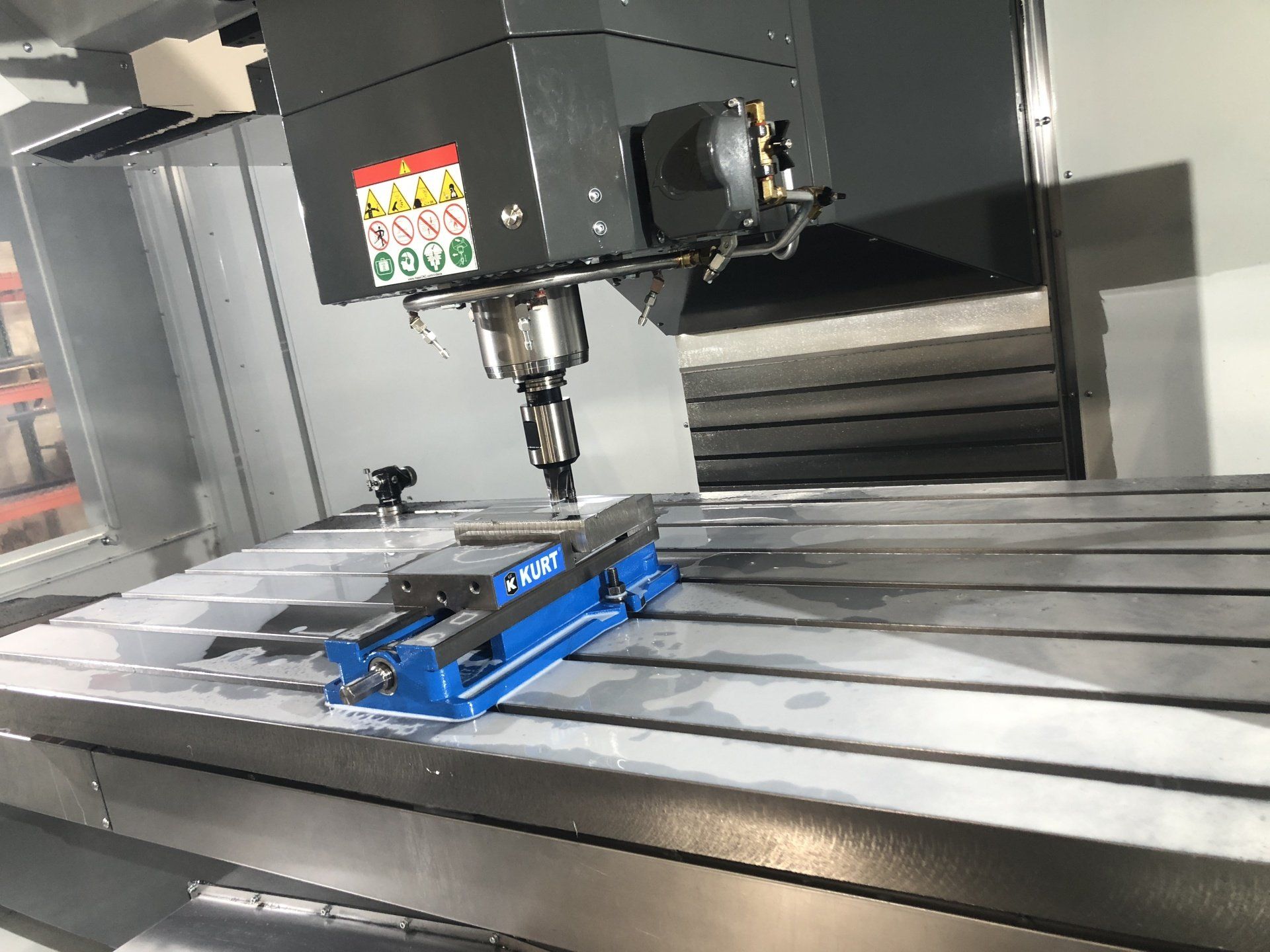

Our two 5-axis Waterjet Cutting Machines are large gantry waterjet cutting machines that are CNC controlled with a fully articulated wrist and can accommodate pieces up to 120″ x 72″.

Our flat sheet, dual head Waterjet Cutting Machine can accommodate pieces up to 144″ x 96″ and can accommodate cutting two 4′ x 8′ sheets at the same time making it an ideal production ready system.

Our Waterjet Cutting Services can process virtually any material quickly and leaves a smooth finish that meets aerospace standards. Utilized in the production of components as thin as aerospace titanium to as thick as military armament, EBTEC can handle any waterjet cutting production challenge.

Contact Us

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Please try again later.