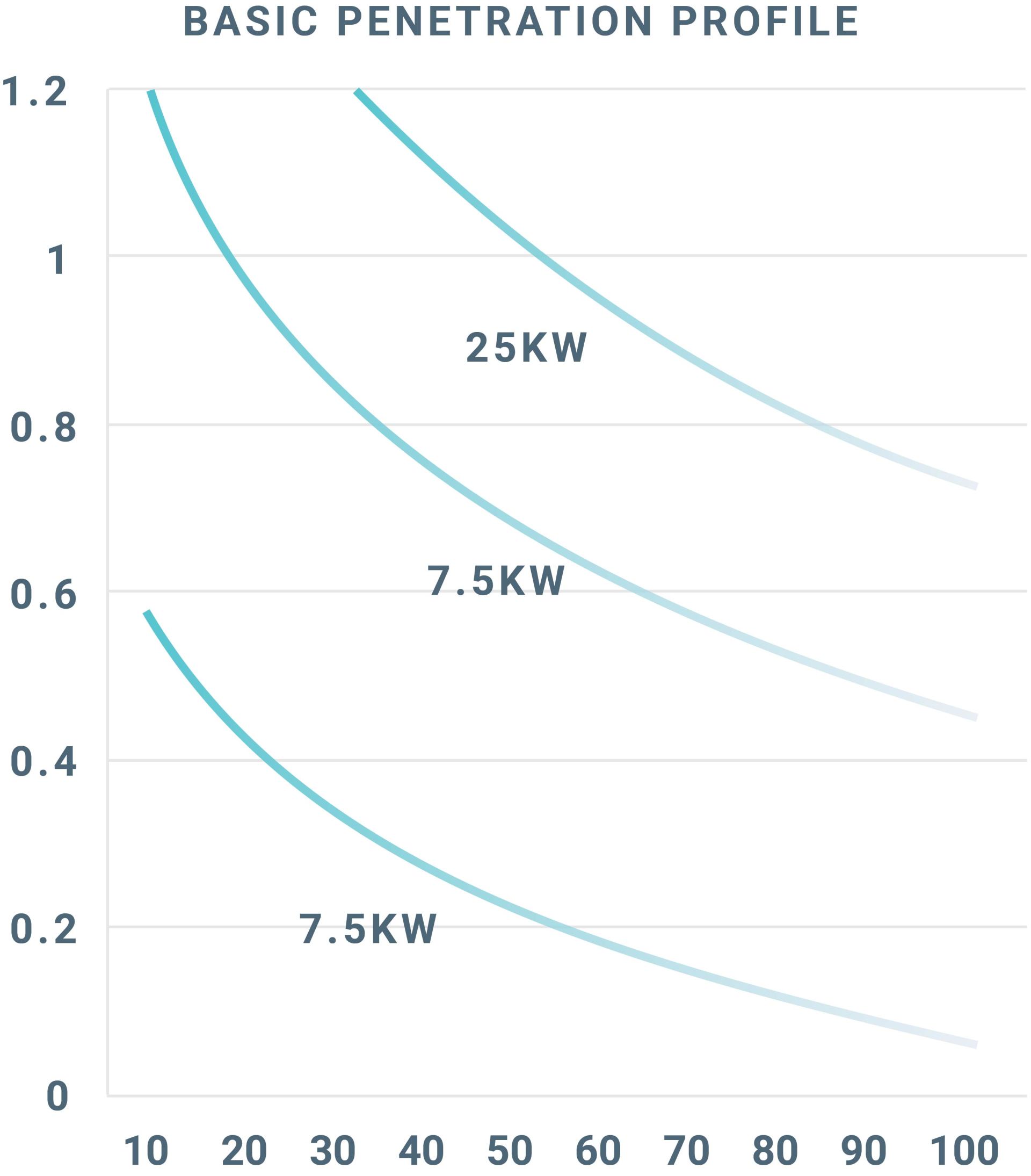

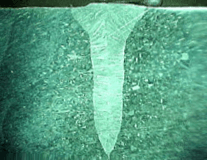

EB Welding Speed/Depth

EB Welding Speeds and Depth of Penetration

Electron Beam (EB) Welding is often chosen over convention methods and has many advantages.

The electron beam welding process is unique in that offers much more repeat-ability, significantly less shrinkage, and considerably higher weld quality than conventional weld processes. Often time’s electron beam welding is more economically feasible than conventional welding. Some electron beam welding application and materials have been seen to maintain up 95% of the strength properties. Titanium, super-alloys, nickel based alloys, cobalt based alloys, high temperature steels, and often times dissimilar material can be joined readily.

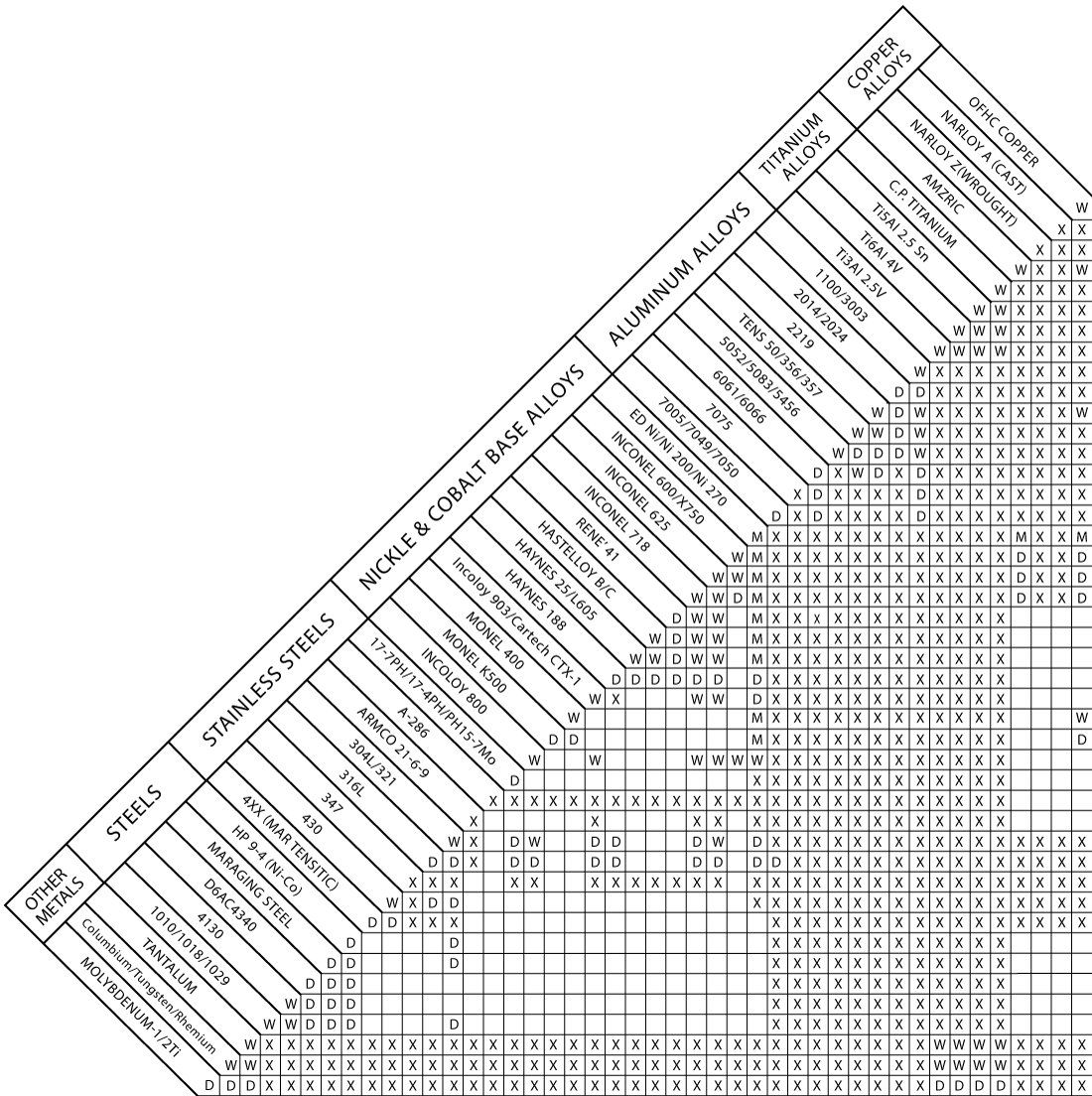

Material Weldability Chart

The materials weld-ability chart below is a valuable reference tool when designing components and materials to be electron beam welded together. Some materials are easily electron beam welded while other are difficult but can be done and of course.....some just should not be tried. Please use this as a guide, it is not mean to be a bible - it is always prudent to contact EBTEC Corporation to speak with an electron beam welding expert, as well as submit weld-ability samples before finalization of design.

W

= Weldable

X = Not recommended (cracking or other problems)

D

= Difficult to weld or requires special techniques

M

= Difficult to weld - magnetic deflection problems

Blank

= Weldability unknown

Notes:

1) Free machining grade alloys, such as 416, 420F, 430F,

and 303 are not suitable for electron beam weldingNew Paragraph

-

About EB Welding

LEARN MORE -

The Value of EB Welding

LEARN MORE -

EB Welding Speed/Strength

LEARN MORE -

EB Machine Process

LEARN MORE

Contact Us

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Please try again later.