The Waterjet Process

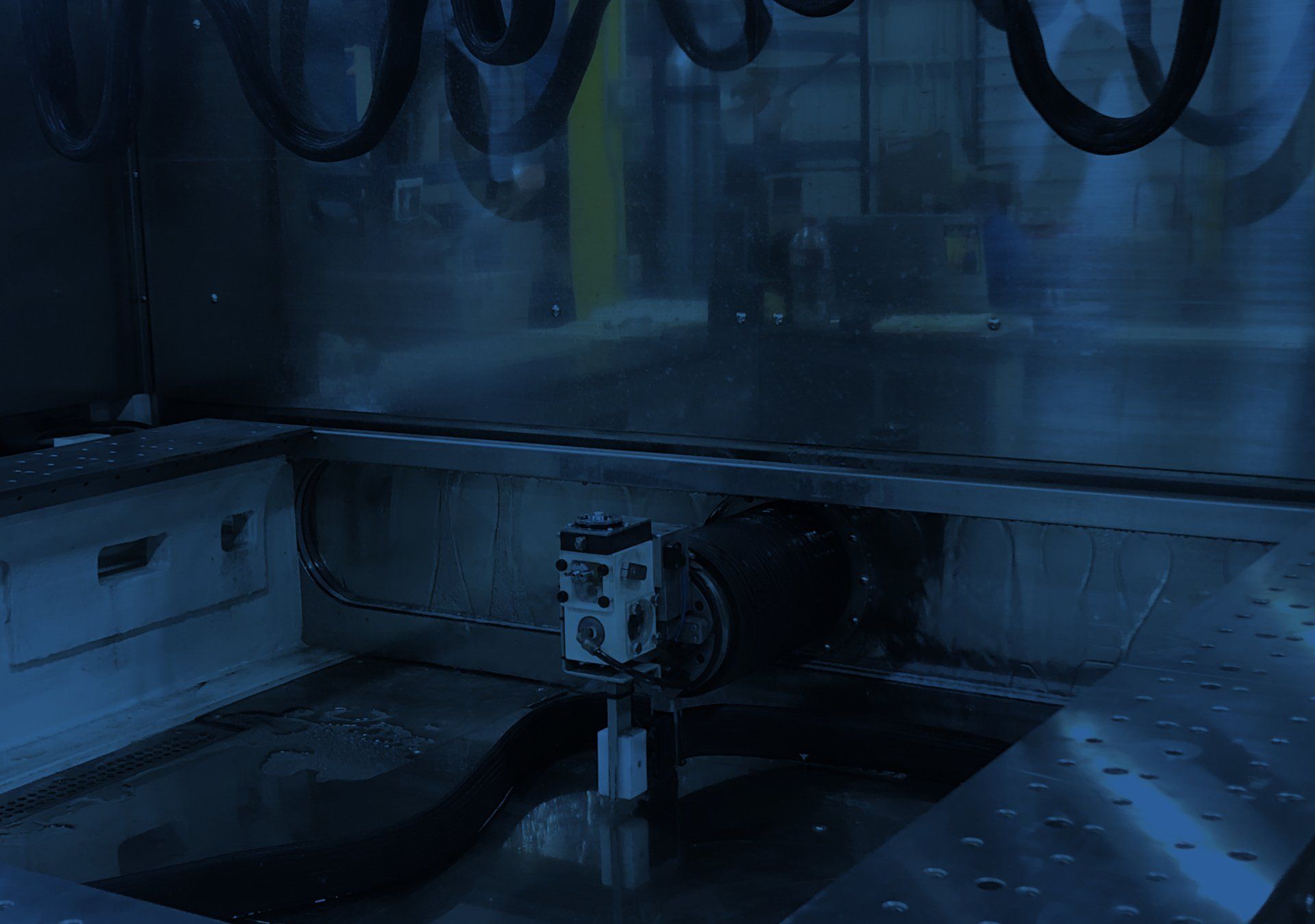

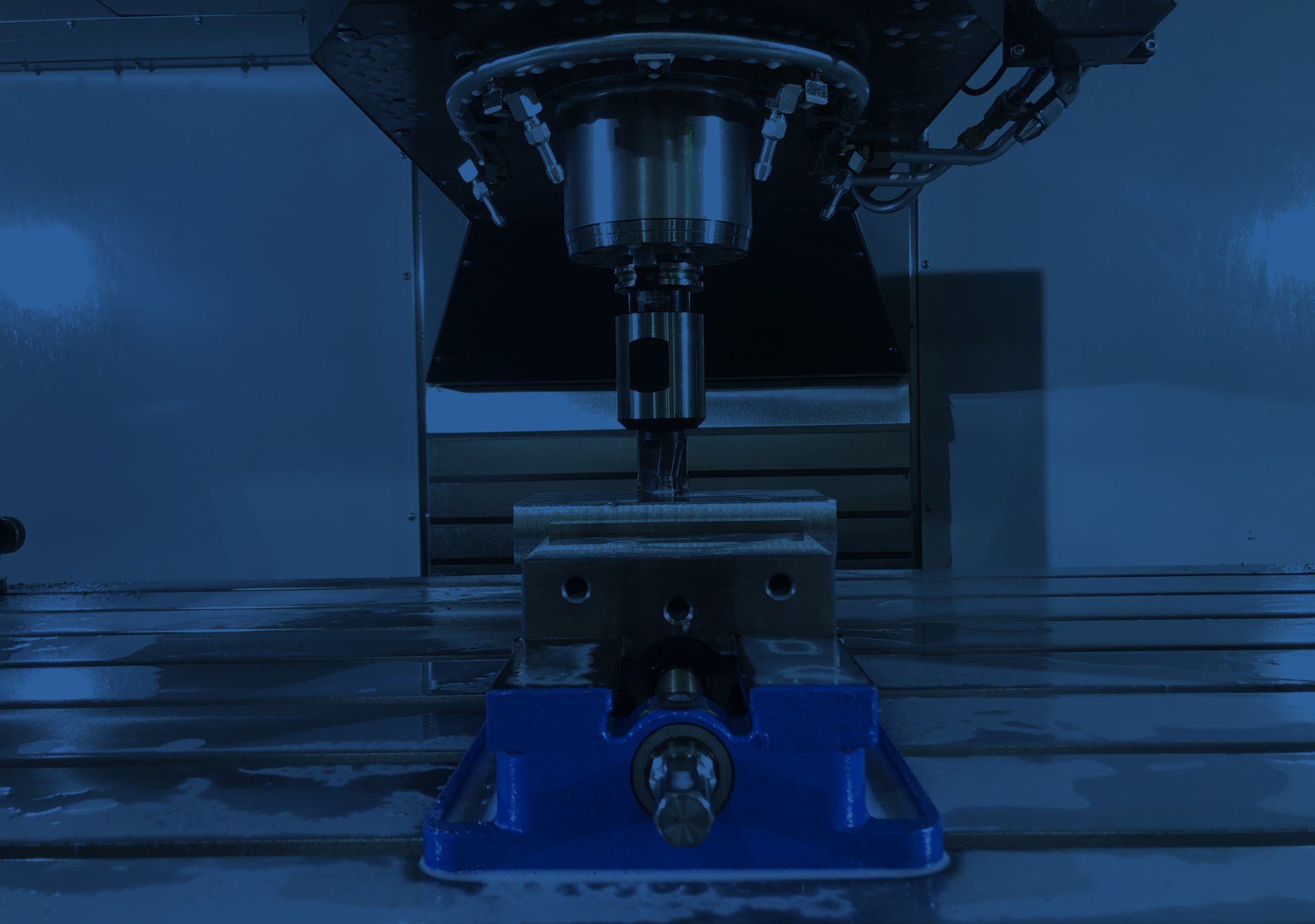

The Waterjet Cutting Process

High-pressure water as a work tool has reached the machine tool industry with great benefits.

The Abrasive Waterjet Cutting process is controlled with CNC programming and can hold tolerances normally associated with Laser Cutting. Our Abrasive Waterjet Cutting system has 5-axis controls, allowing for complex geometries, as well as flat sheet processing capabilities. The Abrasive Waterjet Cutting system operates at a maximum pressure of 55,000 psi (technology is allowing for the introduction of higher pressure capabilities), flowing through a ceramic orifice and mixing tube.

The pressures required to operate the Waterjet Cutting (and abrasive water jet system) system are generated through high-pressure intensifiers (pumps) and high-pressure attenuators (smoothening the peaks and valleys of the pumps).

The orifice finely focuses the water stream to a pinpoint, creating an intense water stream projection. The Abrasive Waterjet Cutting system’s mixing tube facilitates the introduction of a cutting media; typically the abrasive material is garnet. The combination of expulsion from the nozzle at speeds reaching 2.5 times the speed of sound, and the near homogenous mixture of abrasive and water, creates an extremely powerful cutting device.

-

About Waterjet Cutting

LEARN MORE -

The Value of Waterjet Cutting

LEARN MORE -

Waterjet Cutting Finishes

LEARN MORE -

The Waterjet Cutting Process

LEARN MORE

Contact Us

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Please try again later.