The Value of Electron Beam Welding

The Value of Electron Beam Welding

The Benefits of EB Welding

- Receive the maximum amount of weld penetration with the least amount of heat input, resulting in reducing distortion

- EB Welding often reduces the need for secondary operations

- Highly repeatable through digital control and frozen processes

- A cleaner, stronger, and homogeneous weld is produced in a vacuum

- The electron beam machine’s vacuum environment eliminates atmospheric contaminants in the weld

- Exotic alloys and dissimilar materials can be welded

- Extreme precision due to CNC programming and magnification of operator viewing

- Electron Beam Welding frequently yields a 0% scrap rate

- The electron beam process can be used for salvage and repair of new and used components

The Limitations of EB Welding

- Evacuation time – creation of vacuum environment – EBTEC remediates this with high pump down speeds and greater part densities with tooling into each cycle

- High Capital Costs – with 11 electron beam machines on premise, EBTEC mitigates that Capital Expense to place equipment within your facility

- Work Chamber size restraints – with 11 machines varying from 1 cubic-foot to 1404 cubic-feet, EBTEC has a machine that fits your specific needs.

-

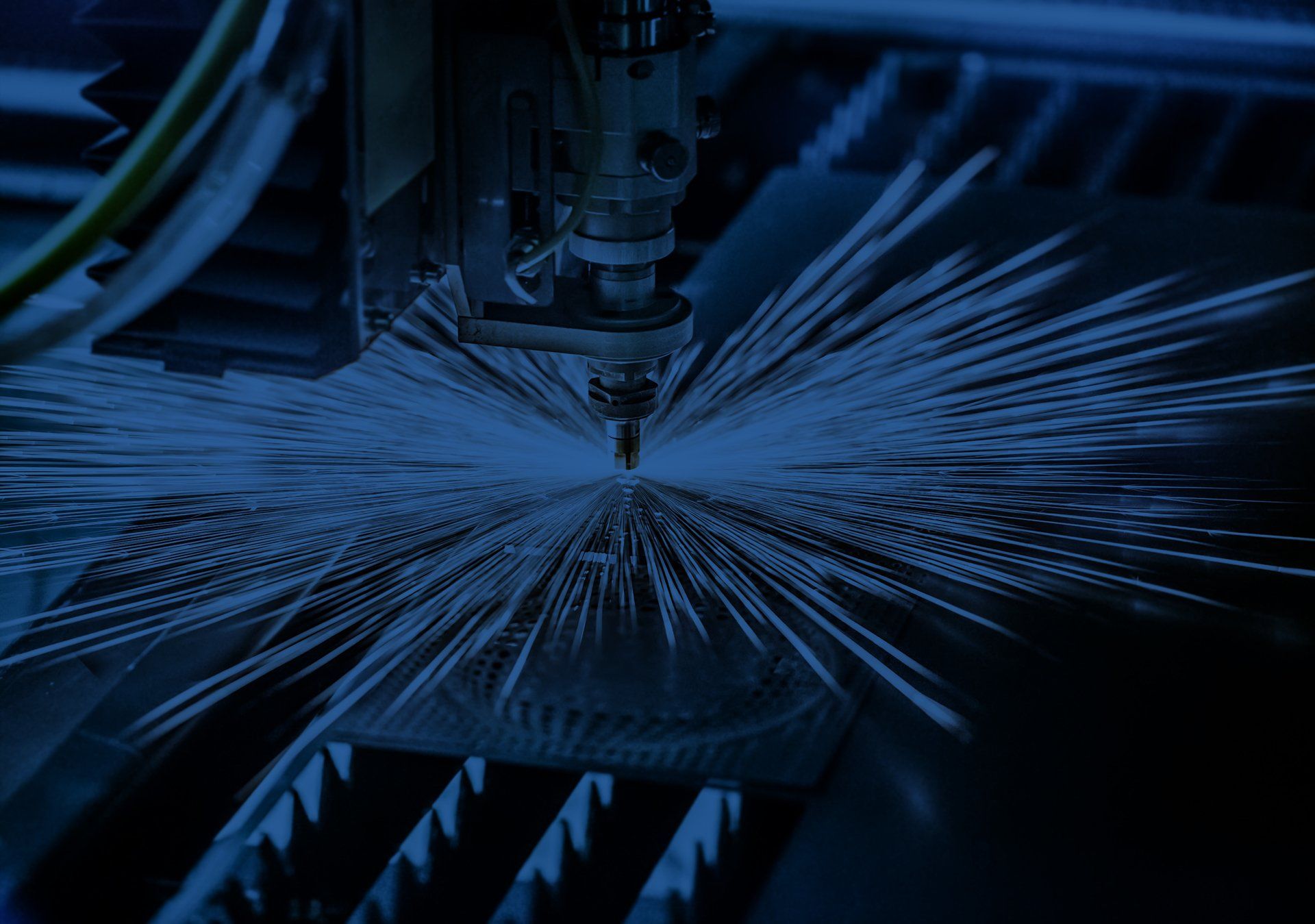

About EB Welding

LEARN MORE -

The Value of EB Welding

LEARN MORE -

EB Welding Speed/Strength

LEARN MORE -

EB Machine Process

LEARN MORE

Contact Us

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Please try again later.